So last weekend, I decided that I should fix my bathroom faucet that had become loose in it’s mounting hole. The hot water tap would shift around when you opened and closed it. The tap functioned alright, it would just shift around which was very annoying. They are very classy American Standard Green Tea fixtures and the loose tap made them seem cheap and tacky.

I’ve tried to tighten them from the underside once or twice before, but couldn’t get it tight enough. The tap just kept loosening up and shifting again. More than just a little frustrating, I hate crawling under the bathroom sink and working upside down in a space too small for a hobbit.

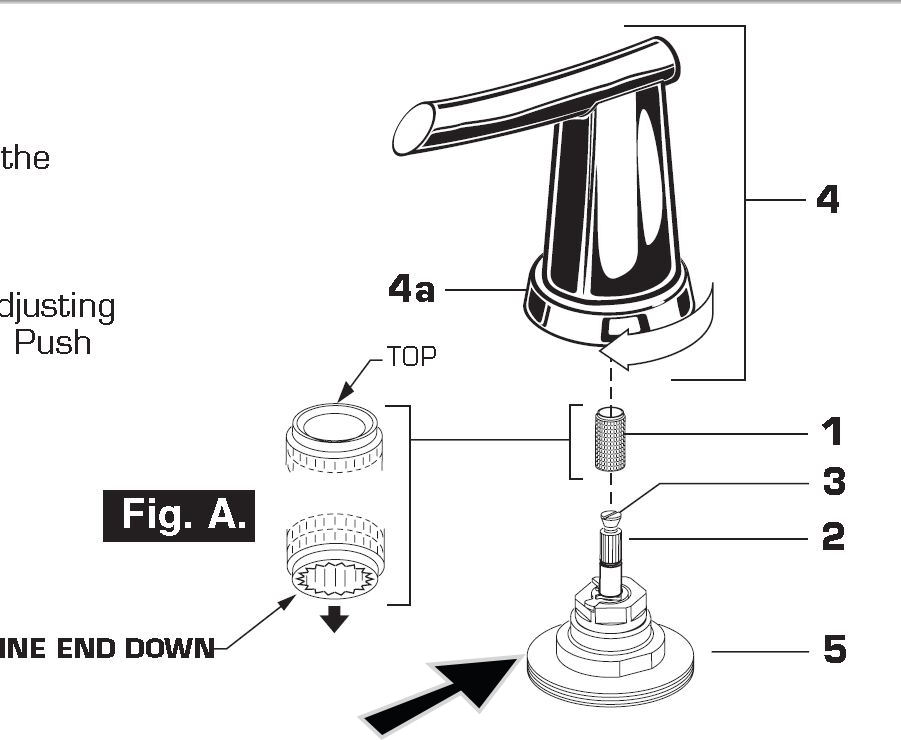

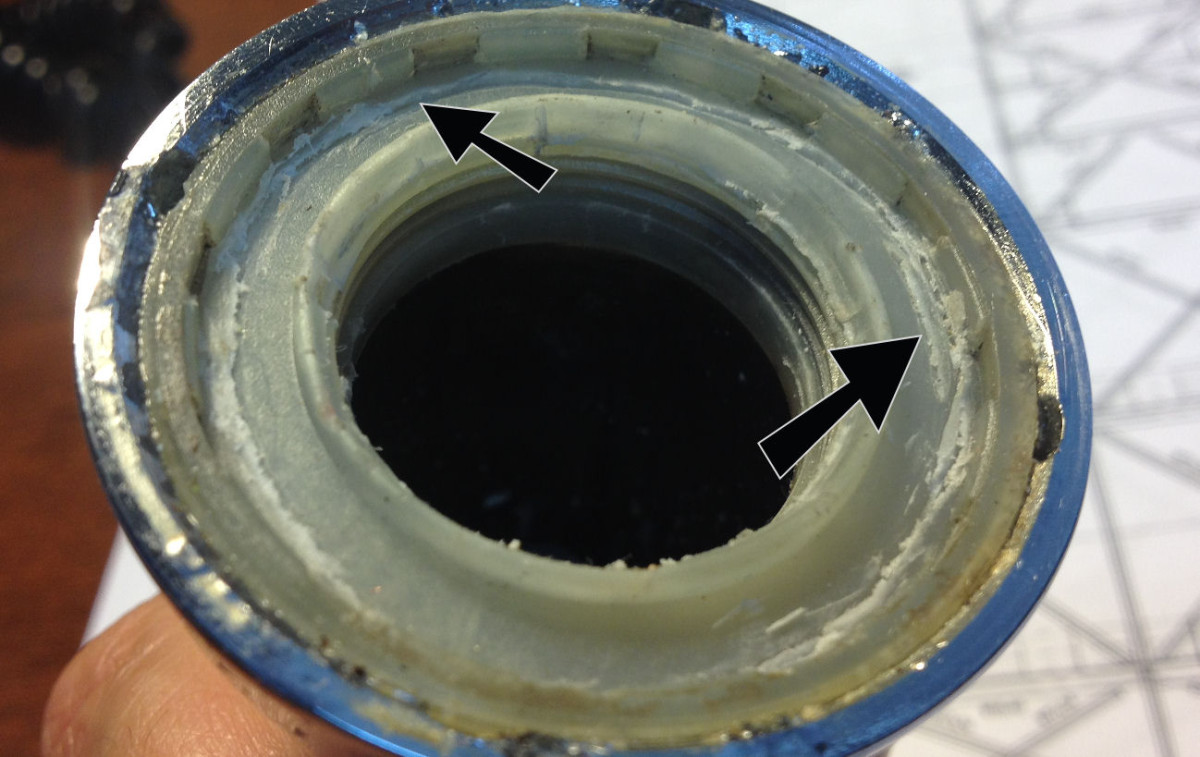

First problem I encountered was that the locking ring was seized on the bezel. It would not simply twist off. So out come the wrenches and the more I worked on it, the more I was marking up the pretty chrome bezel. Cursing to myself, because with each new little scuff, I knew I was getting closer to having to purchase a new faucet set (expensive). Finally, I worked the tap handle off the valve and found that the locking ring was gummed up with corrosion and calcium which locked that ring in good. I had to turn the soft nylon ring out of the tap handle somehow which looked nearly impossible. I tried a few different ways which only succeeded in marring the ring and I started to destroy the ring. Again, frustration increasing as I knew I was getting closer and closer to having to purchase a new set.

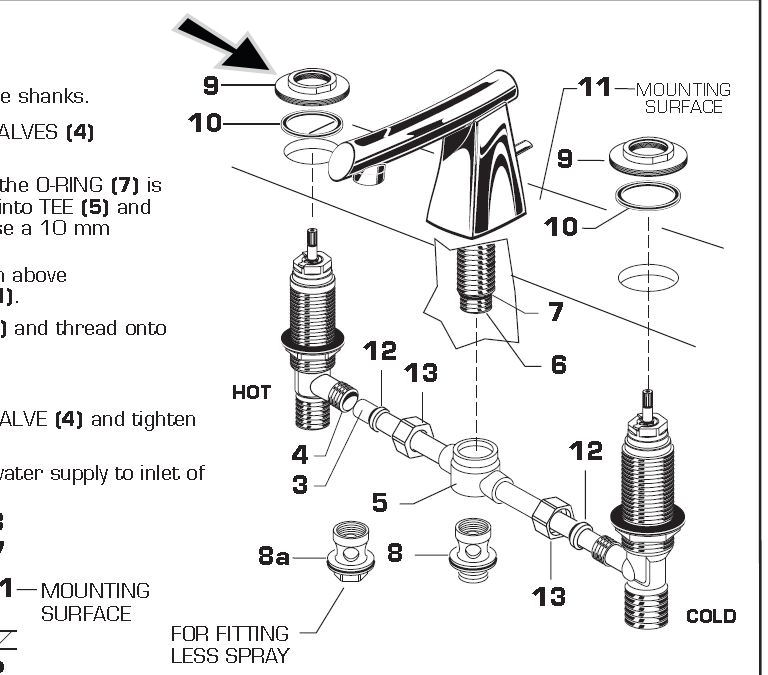

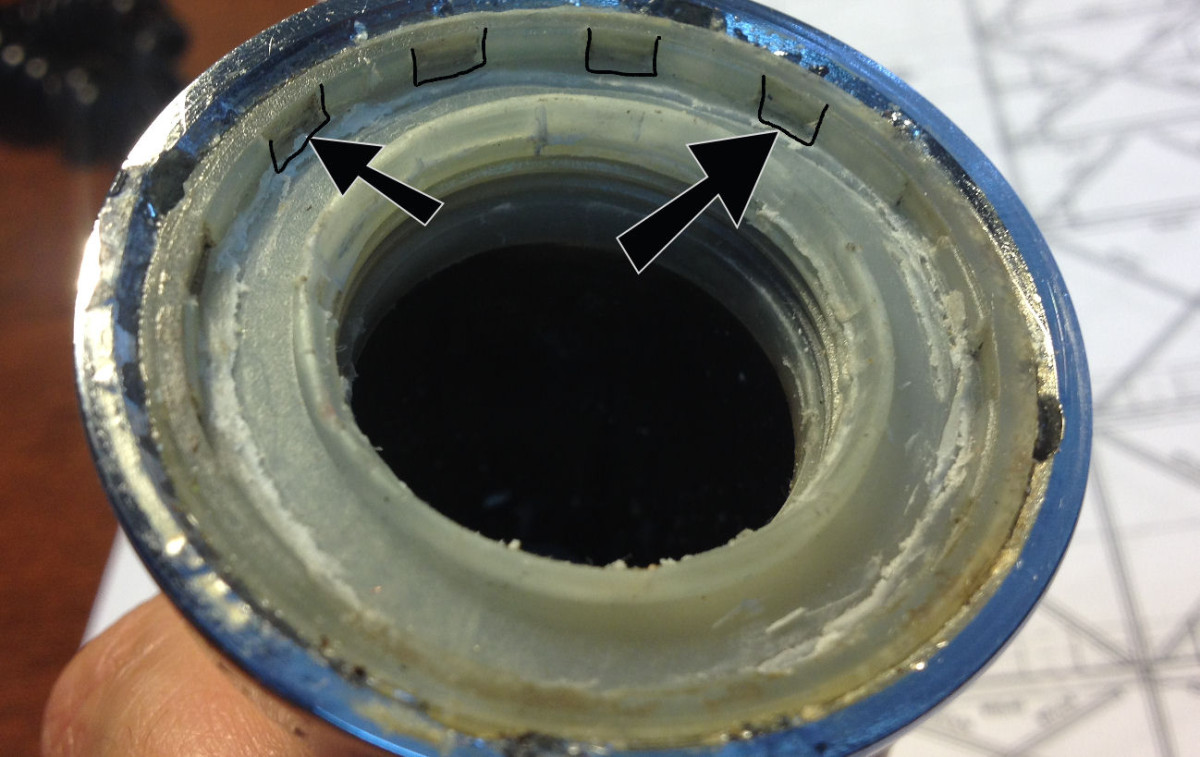

So the problem – how to get that stupid little locking ring out of the bezel. I noticed that the ring had an internal 12 point spline keyway that would work good, but now who’s got an external 12 point spline tool 1.6″ diameter in their toolbox? The tool only exists in the factories of American Standard or in some designer’s imagination. Then I thought “If only I knew someone with a 3D printer!” Doh!

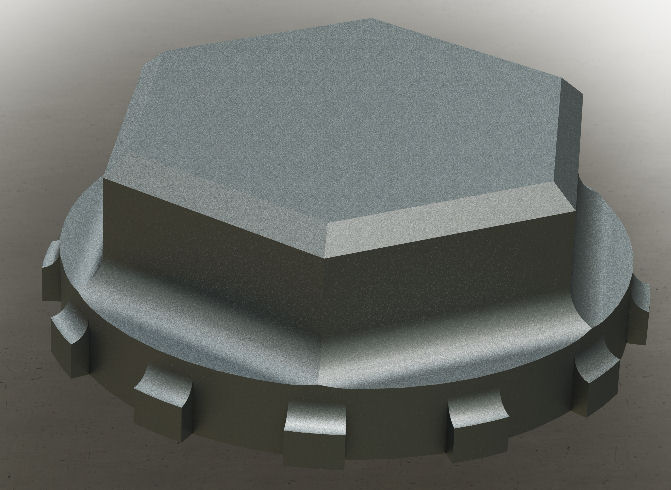

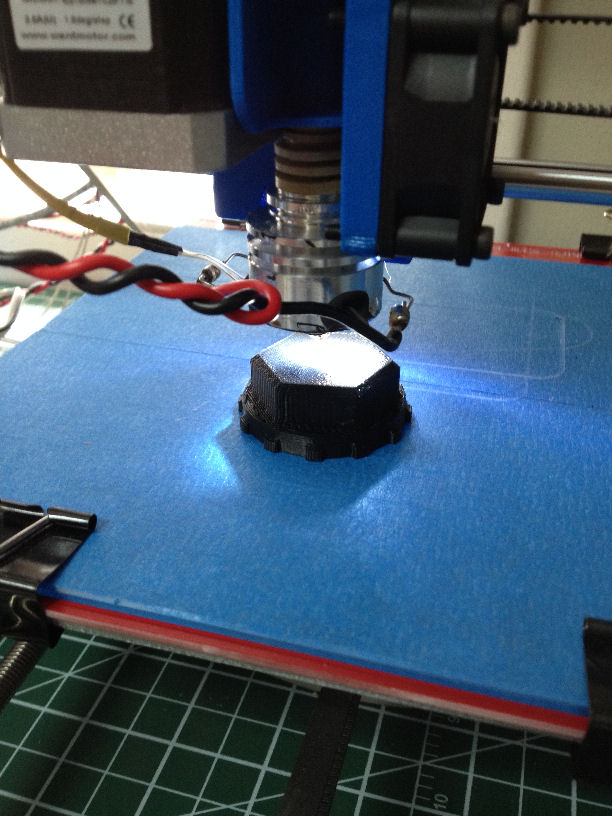

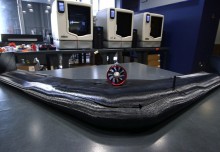

I wandered over to the office and whipped up a quick design of the tool that would work and fired it off to the printer.

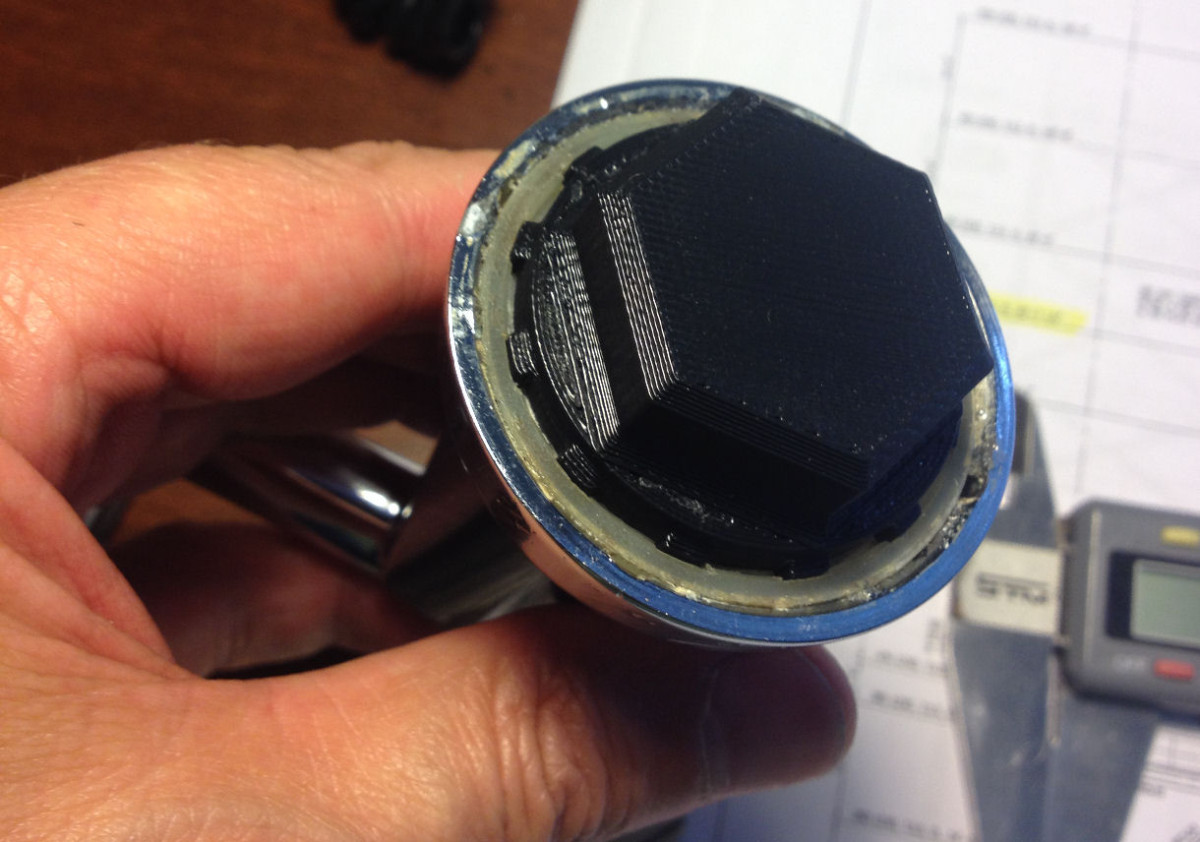

An hour later, I was working that ring out and although it was tough, it came out! I was able to clean it up and re-install the valve back and tightened it properly without destroying the nylon ring. Taps work perfectly now. Nice and tight with no wobble.

Note to American Standard – If you insist on goofy designs like this, please supply the tools to work on these things. This ring should be made of brass instead of the soft nylon and the 12 point external spline tool should be part of the package – no?