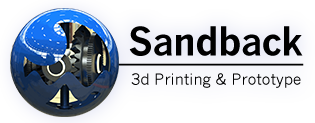

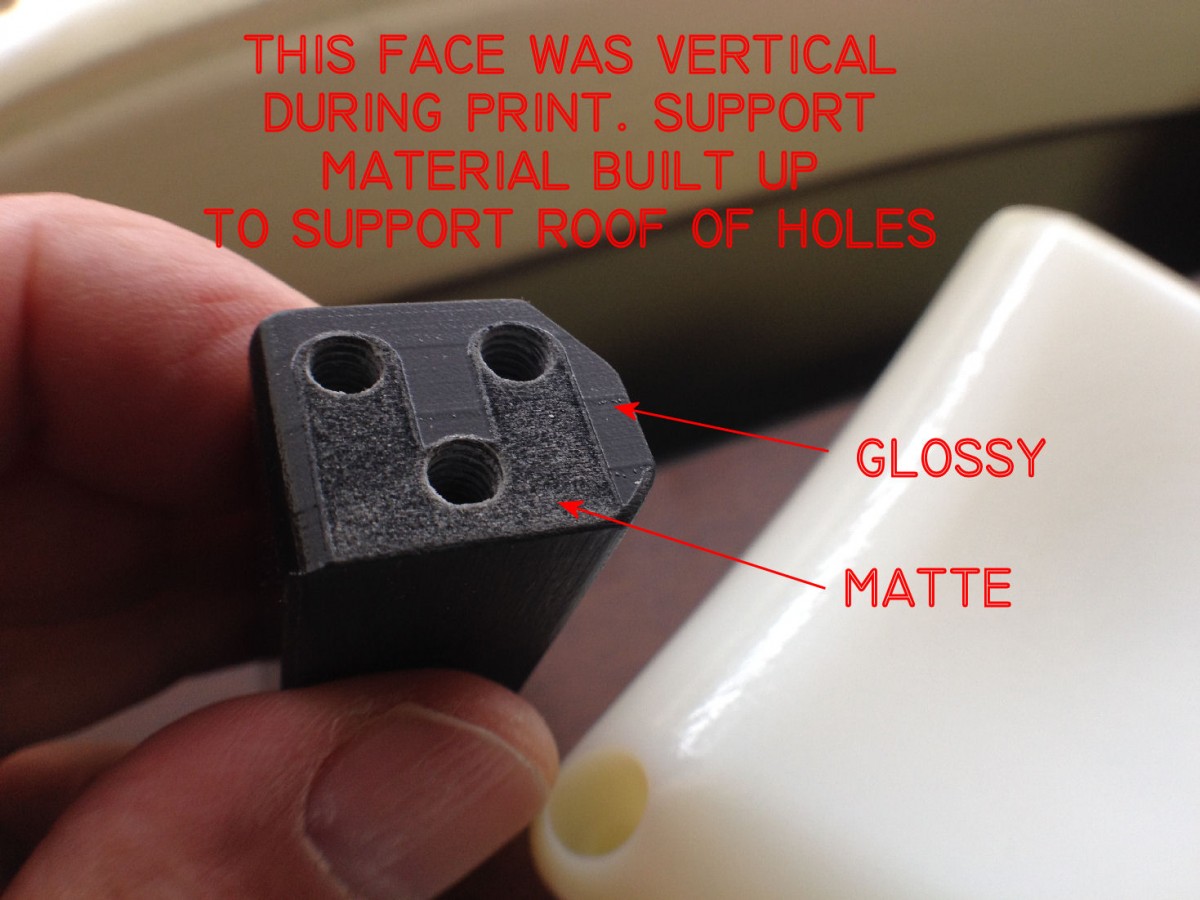

This is the first of a series of texture studies examining the various materials and technologies available to us. This first entry is VeroBlack printed on an Objet30 Stratasys machine. This is a wonderful piece because it gives you a wide range of textures from matte to glossy and effects of scaffolding or support material when it touches a vertical surface. When ever there is material overhang, the layers of model material must be supported by support material as it is cured layer by layer.

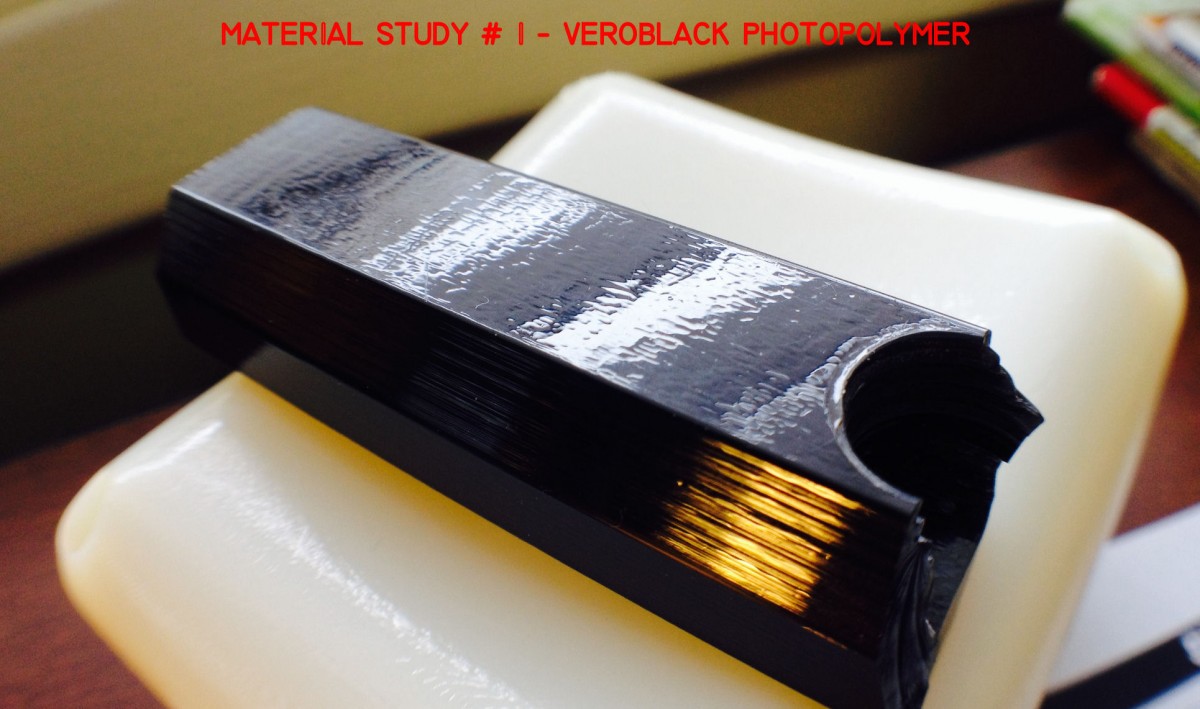

The part was to be threaded with a 1/8″ NPT pipe thread which worked perfectly, but the tap was turned too deep and the part fractured at the weakest point. This gives us a nice window into the interior material composition of the process. As you can see, it is a very homogeneous structure similar to glass. There are no layer striations as each layer of resin is bonded to the layer below as it is being printed.

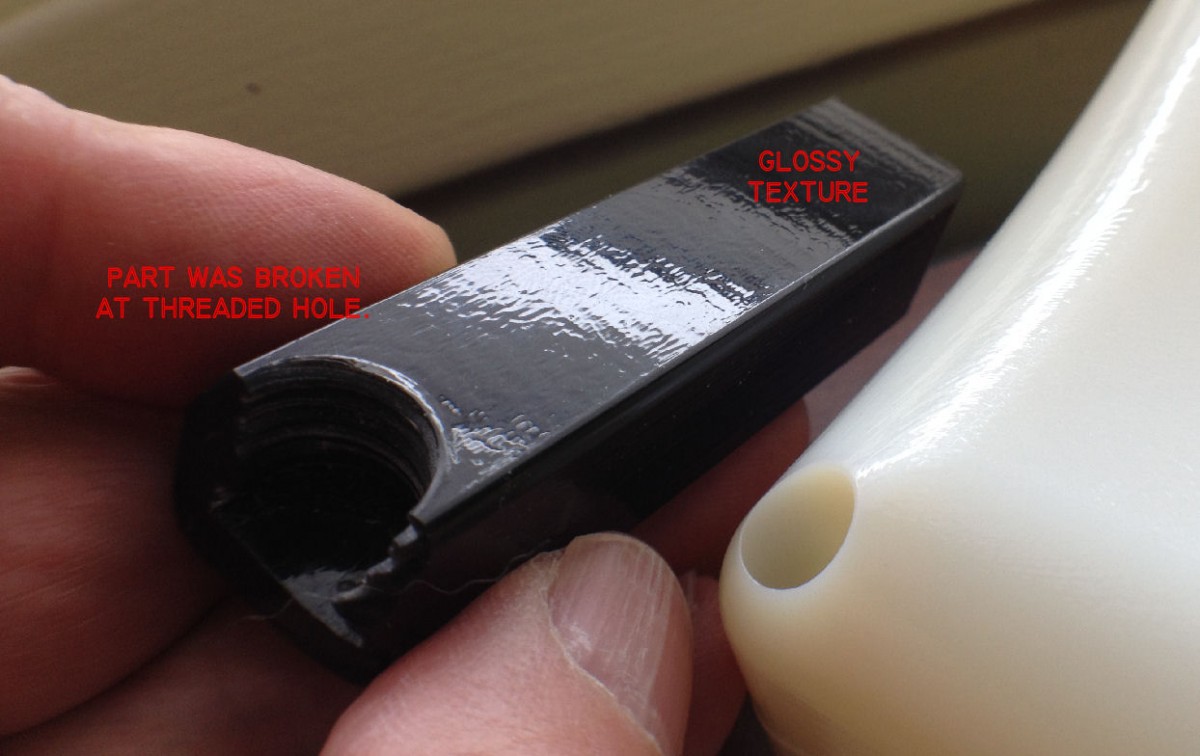

The top surface is a very glossy finish. There are slight imperfections of the resin from the effects of the pressure roller on the material as it is layed down on the printer deck.

Vertical faces with overhangs or holes in them will have support material built up the sides to support the overhangs. The effects of the support material on the glossy surface is that the model material mixes with the support material and we have the resulting matte finish.

A glossy vertical face will be very shiny, but still have the smooth striations of the layering. The layers are 28 microns thick and very hard to pick out, but will still give the part the distinctive ripple effect.

The bottom surface will have a flat matte finish because it is built up on top of the support material. A surface that is touching support material and that is overhanging or on an angle will have a ‘furry’ or ‘feathered’ texture as the edges of the model material mixes with the support material.

Tiny holes are not a problem with the pJet process. Threads and threading are not a problem either, but for small threaded parts, I prefer to make the tap hole to size and cut threads with a tap instead. Do not try to force form threads into this type of material as it will break and fracture.

Hope this helps with the texture questions on the Vero Family of photopolymer materials.